Typical Obstacles in Welding Inspection Madison and How to Overcome Them

Typical Obstacles in Welding Inspection Madison and How to Overcome Them

Blog Article

How Efficient Welding Assessment Boosts Architectural Honesty and Longevity

In the world of building and engineering, the significance of welding assessment can not be overemphasized, as it plays an essential function in making certain structural integrity and prolonging the life expectancy of projects. Sign up with the exploration of how effective welding examinations can change possible susceptabilities right into staminas, adding to the enduring success of building and constructions.

Importance of Welding Examination

Guaranteeing the architectural integrity and security of bonded constructions requireds strenuous welding evaluation procedures. Welding inspection offers as an important guard in the construction and production sectors, where the stamina and durability of joints substantially influence the overall performance of structures. This assessment ensures that welds satisfy details standards and specs, decreasing the threats connected with structural failings. The repercussions of inadequate welds can be disastrous, resulting in costly fixings, functional downtimes, or perhaps disastrous failures, all of which highlight the vital importance of complete inspection.

In addition to security, welding inspection plays an important duty in top quality guarantee. By adhering to predetermined criteria, evaluations determine the uniformity of welds, guaranteeing that each meets the preferred stamina and visual requirements. This uniformity is crucial not only for security but likewise for maintaining the reputation and dependability of fitters and makers. Additionally, governing conformity is a significant motorist of welding examination methods. Industry standards and codes, such as those from the American Welding Culture (AWS) or the International Organization for Standardization (ISO), necessitate adherence to rigorous standards, underscoring the relevance of evaluations in fulfilling these lawful and expert commitments.

Trick Assessment Strategies

Ultrasonic Evaluating (UT) uses high-frequency acoustic waves to discover subsurface imperfections, offering precise info regarding weld honesty without creating any kind of damage. Radiographic Testing (RT), including X-rays or gamma rays, gives a detailed picture of the weld's internal structure, revealing covert flaws. Magnetic Bit Checking (MPT) is one more non-destructive technique, especially efficient for identifying surface area and near-surface gaps in ferromagnetic materials.

Penetrant Testing (PT) includes the application of a liquid dye to reveal surface-breaking defects, offering a straightforward and cost-effective service for non-porous materials. Each technique has its details applications, strengths, and limitations, and often a combination of methods is utilized to accomplish detailed assessment results. Mastery of these methods improves the dependability and durability of welded structures, aligning with security and efficiency expectations.

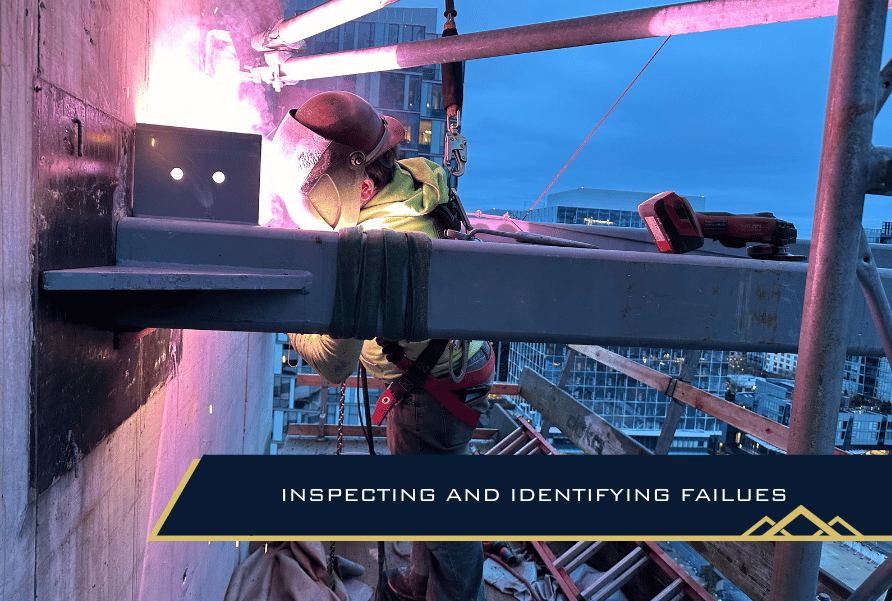

Identifying Common Problems

Porosity, identified by gas pockets within the weld, minimizes the weld's toughness and longevity. It often results from pollutants or inappropriate shielding gas. Fractures, which can happen throughout or after welding, position considerable threats due to their prospective to circulate under stress. They typically emerge from extreme anxiety, quick air conditioning, or improper weld style.

Insufficient blend, where the weld steel falls short to bond entirely with the base product, threatens the architectural honesty, leading to weak joints. This defect generally comes from inadequate warm input or incorrect welding strategy. Slag additions take place when non-metallic products are entraped in the weld, endangering its toughness and top quality. These are often a result of poor cleansing in between weld passes or improper flux usage.

Recognizing these flaws with meticulous inspection approaches, such as visual assessment, ultrasonic testing, or radiography, is crucial. Addressing these problems makes sure weld high quality, ultimately sustaining the structural honesty and security of the built atmosphere.

Enhancing Structural Performance

Recognizing the importance of recognizing common weld problems normally leads to checking out approaches for enhancing structural efficiency. The fundamental method for enhancing efficiency entails utilizing innovative welding techniques and materials that alleviate issue occurrence. Using high-grade filler materials and making sure correct heat control can significantly lower concerns such as porosity and breaking, consequently boosting the weld's honesty.

Incorporating cutting edge welding modern technologies, such as laser welding and friction mix welding, more amplifies structural strength. These techniques use remarkable precision and minimized thermal distortion, directly affecting the toughness and toughness of the bonded structures. Furthermore, taking on automated welding systems can ensure repeatable and constant weld high quality, lessening human mistake.

Additionally, implementing rigorous pre-weld and post-weld procedures is crucial. Appropriate joint design, surface prep work, and stress-relieving procedures contribute to ideal weld efficiency. Carrying out extensive pre-weld assessments permits early detection of prospective problems, helping with timely improvements prior to they jeopardize the framework.

Lasting Benefits of Inspection

Via attentive evaluation practices, the long-lasting benefits to architectural integrity ended up being increasingly noticeable. Extensive and consistent welding assessments play an important duty in avoiding architectural failures by view publisher site determining inconsistencies and flaws early in the construction process. This aggressive approach makes sure that possible issues are attended to prior to they can compromise the security and longevity of structures. By catching issues early, costly repair work and downtime are decreased, ultimately prolonging the life expectancy of the framework.

Furthermore, regular evaluations add to maintaining compliance with market standards and policies, consequently staying clear of monetary and legal repercussions. This adherence to quality control not just boosts the integrity of the framework however also fosters trust fund amongst stakeholders, consisting of clients, engineers, and governing bodies. The thorough paperwork of assessment results functions as a beneficial source for future upkeep and repair his explanation work efforts, promoting notified decision-making.

Furthermore, effective examination methods support technology by integrating sophisticated technologies such as non-destructive screening and digital imaging, which can improve precision and efficiency. This technical combination further emphasizes the commitment to quality in structural integrity. Inevitably, buying thorough welding assessments is a prudent method that yields substantial lasting advantages, guarding both the physical and monetary financial investment in infrastructure jobs.

Conclusion

Reliable welding evaluation plays a crucial duty in improving architectural integrity and durability by identifying flaws early in the building procedure. Utilizing strategies such as visual examination, ultrasonic testing, and radiographic screening guarantees the discovery of issues like splits and porosity that endanger weld strength. Extensive examinations ensure compliance with market criteria, thereby extending the life expectancy of frameworks, decreasing costly repair work, and promoting stakeholder rely on the integrity and safety of bonded building and constructions.

In the realm of building and design, the relevance of welding inspection can not be overstated, as it plays a critical function in making sure architectural honesty and expanding the lifespan of projects.Ensuring the structural honesty and safety of welded constructions mandates rigorous welding evaluation processes.Building upon the significance of welding inspection in safeguarding structural honesty, recognizing the vital examination strategies comes to be important for effective implementation. Effective welding inspection incorporates an array of techniques developed to assess weld high quality, ensuring conformity with rigorous engineering standards - Welding Inspection Madison.Reliable welding examination plays an essential duty in improving structural integrity visit site and longevity by recognizing flaws early in the building process

Report this page